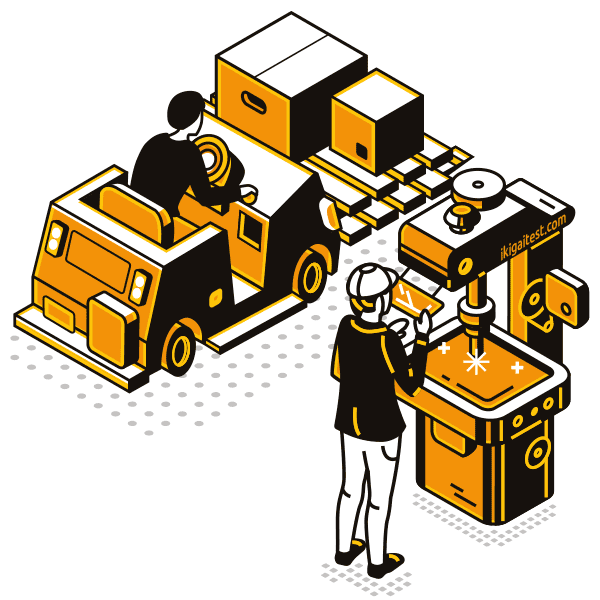

Operator

Operators are expected to be good at:

- Using either control mechanisms or direct physical activity to operate manufacturing systems.

- Working with hand operated industrial machines and power tools.

- Adjusting knobs, levers, and physical or touch sensitive buttons in industrial devices.

- Running, maneuvering, navigating, or driving vehicles or mechanized equipment, such as forklifts, passenger vehicles, aircraft, or watercraft.

Artisan

Great artisans are usually capable of:

- Using hands and arms in handling, installing, positioning, and moving materials.

- Performing precise and skillful manipulation of small objects.

- Being active and proactive in regards to physical activities that require considerable use of your arms and legs and moving your whole body, such as climbing, lifting, balancing, walking, stooping, and handling materials.

Other work activities related to Drilling and boring machine tool setters, operators, and tenders, metal and plastic

- Verifying conformance of machined working to specifications, using measuring instruments, such as calipers, micrometers, or fixed or telescoping gauges.

- Studying machining instructions, job orders, or blueprints for determining the dimensional or finishing specifications, sequences of operations, setups, or tooling requirements.

- Selecting and setting cutting speeds, loading rates, depths of cuts, and cutting tools, according to machining instructions or knowledge of metal properties.

- Installing tools in spindles.

- Changing worn cutting tools, using wrenches.

- Positioning and securing workpieces on tables, using bolts, jigs, clamps, shims, or other holding devices.

- Moving machine controls for lowering tools to workpieces and for engaging automatic feeds.

- Turning valves and directing flow of coolants or cutting oil over cutting areas.

- Operating single or multiple spindle drill presses for boring holes so that machining operations can be performed on metal or plastic workpieces.