Operator

Operators are expected to be good at:

- Using either control mechanisms or direct physical activity to operate manufacturing systems.

- Working with hand operated industrial machines and power tools.

- Adjusting knobs, levers, and physical or touch sensitive buttons in industrial devices.

- Running, maneuvering, navigating, or driving vehicles or mechanized equipment, such as forklifts, passenger vehicles, aircraft, or watercraft.

Supervisor

Any supervisor should excel at:

- Monitoring and reviewing information from materials, events, or the environment.

- Detecting or assessing problems whether real or potential.

- Monitoring and controlling resources and overseeing the spending of money.

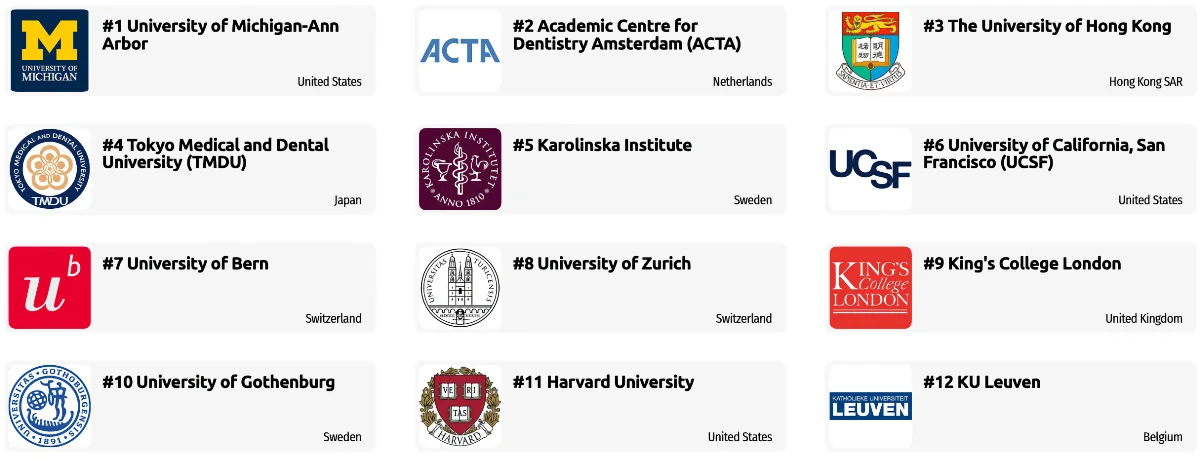

Other work activities related to Dental laboratory technicians

- Reading prescriptions or specifications and examining models or impressions for determining the design of dental products to be constructed.

- Fabricating, altering, or repairing dental devices, such as dentures, crowns, bridges, inlays, or appliances for straightening teeth.

- Testing appliances for conformance to specifications and accuracy of occlusion, using articulators and micrometers.

- Placing tooth models on apparatus that mimics bite and movement of patient’s jaw for evaluating functionality of model.

- Melting metals or mixing plaster, porcelain, or acrylic pastes and pouring materials into molds or over frameworks for forming dental prostheses or apparatus.

- Removing excess metal or porcelain and polishing surfaces of prostheses or frameworks, using polishing machines.

- Creating a model of patient’s mouth by pouring plaster into a dental impression and allowing plaster to setting.

- Loading newly constructed teeth into porcelain furnaces for baking the porcelain onto the metal framework.