Operator

Operators are expected to be good at:

- Using either control mechanisms or direct physical activity to operate manufacturing systems.

- Working with hand operated industrial machines and power tools.

- Adjusting knobs, levers, and physical or touch sensitive buttons in industrial devices.

- Running, maneuvering, navigating, or driving vehicles or mechanized equipment, such as forklifts, passenger vehicles, aircraft, or watercraft.

Artisan

Great artisans are usually capable of:

- Using hands and arms in handling, installing, positioning, and moving materials.

- Performing precise and skillful manipulation of small objects.

- Being active and proactive in regards to physical activities that require considerable use of your arms and legs and moving your whole body, such as climbing, lifting, balancing, walking, stooping, and handling materials.

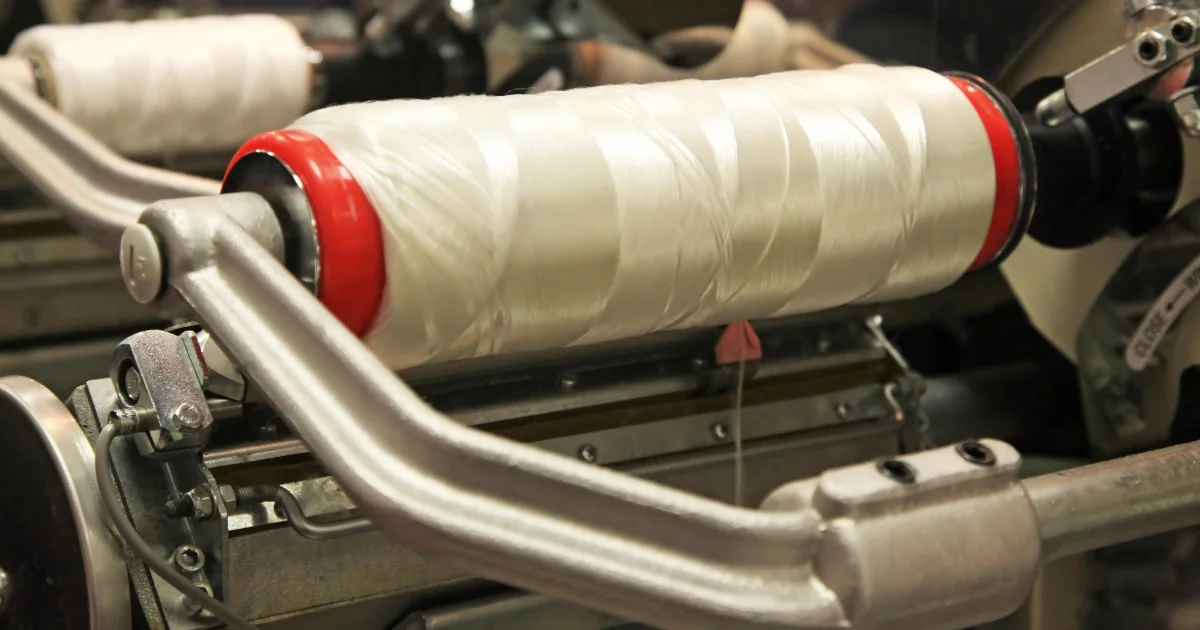

Other work activities related to Textile winding, twisting, and drawing out machine setters, operators, and tenders

- Notifying supervisors or mechanics of equipment malfunctions.

- Starting machines, monitoring operation, and making adjustments as needed.

- Tending machines with multiple winding units for winding threads onto shuttle bobbins for using on sewing machines or other kinds of bobbins for sole stitching, knitting, or weaving machinery.

- Inspecting products for verifying that they meet specifications and for determining whether machine adjustment is needed.

- Tending machines for twisting together two or more strands of yarn or inserting additional twists into single strands of yarn for increasing strength, smoothness, or uniformity of yarn.

- Replacing the depleted supplies packages with full packages.

- Observing operations for detecting defects, malfunctions, or supplies shortages.

- Threading yarns, threads, or fabrics through guides, needles, and rollers of machines.

- Operating machines for testing runs for verifying adjustments and for obtaining product samples.

- Inspecting machinery for determining whether repairs are needed.