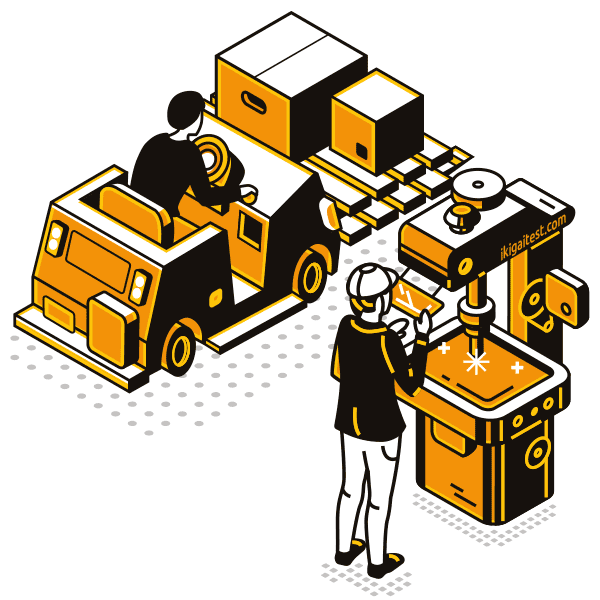

Operator

Operators are expected to be good at:

- Using either control mechanisms or direct physical activity to operate manufacturing systems.

- Working with hand operated industrial machines and power tools.

- Adjusting knobs, levers, and physical or touch sensitive buttons in industrial devices.

- Running, maneuvering, navigating, or driving vehicles or mechanized equipment, such as forklifts, passenger vehicles, aircraft, or watercraft.

Artisan

Great artisans are usually capable of:

- Using hands and arms in handling, installing, positioning, and moving materials.

- Performing precise and skillful manipulation of small objects.

- Being active and proactive in regards to physical activities that require considerable use of your arms and legs and moving your whole body, such as climbing, lifting, balancing, walking, stooping, and handling materials.

Other work activities related to Textile cutting machine setters, operators, and tenders

- Placing patterns on top of layers of fabric and cutting fabric following patterns, using electric or manual knives, cutters, or computer numerically controlled cutting devices.

- Notifying supervisors of mechanical malfunctions.

- Repairing or replacing worn or defective parts or components, using hand tools.

- Adjusting cutting techniques to types of fabrics and styles of garments.

- Inspecting machinery for determining whether repairs are needed.

- Adjusting machine controls, such as heating mechanisms, tensions, or speeds, for producing specified products.

- Inspecting products for ensuring that specifications are met and for determining whether machines require adjustment.

- Conferring with coworkers for obtaining information about orders, processes, or problems.

- Starting machines, monitoring operations, and making adjustments as needed.

- Cleaning, oiling, and lubricating machines, using air hoses, cleaning solutions, rags, oilcans, and grease guns.

- Recording information about working completed and machine settings.