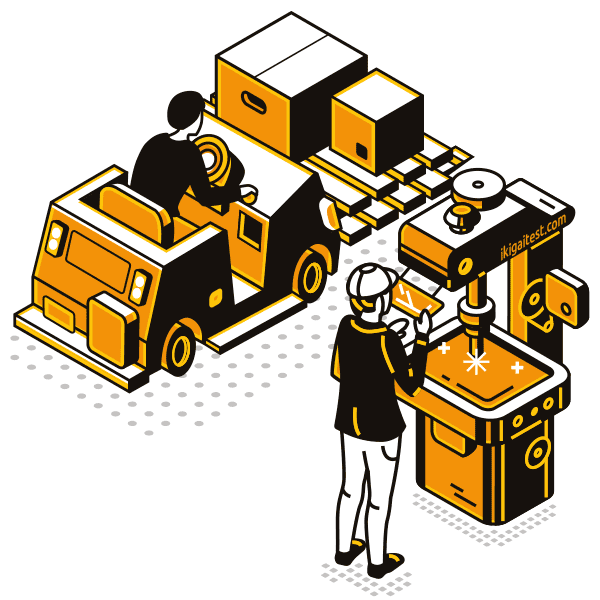

Operator

Operators are expected to be good at:

- Using either control mechanisms or direct physical activity to operate manufacturing systems.

- Working with hand operated industrial machines and power tools.

- Adjusting knobs, levers, and physical or touch sensitive buttons in industrial devices.

- Running, maneuvering, navigating, or driving vehicles or mechanized equipment, such as forklifts, passenger vehicles, aircraft, or watercraft.

Artisan

Great artisans are usually capable of:

- Using hands and arms in handling, installing, positioning, and moving materials.

- Performing precise and skillful manipulation of small objects.

- Being active and proactive in regards to physical activities that require considerable use of your arms and legs and moving your whole body, such as climbing, lifting, balancing, walking, stooping, and handling materials.

Other work activities related to Rolling machine setters, operators, and tenders, metal and plastic

- Adjusting and correcting machine setting ups for reducing thicknesses, reshaping products, and eliminating product defects.

- Monitoring machine cycles and mill operation for detecting jamming and for ensuring that products conform to specifications.

- Examining, inspecting, and measuring raw materials and finished products for verifying conformance to specifications.

- Reading rolling orders, blueprints, and mill schedules for determining setup specifications, working sequences, product dimensions, and installation procedures.

- Manipulating controls and observing dial indicators for monitoring, adjusting, and regulating speeds of machine mechanisms.

- Starting operation of rolling and milling machines for flattening, tempering, forming, and reducing sheet metal sections and for producing steel strips.

- Setting distance points between rolls, guides, meters, and stops, according to specifications.

- Threading or loading sheets or rods through rolling mechanisms, or starting and controlling mechanisms for automatically loading steel into rollers.