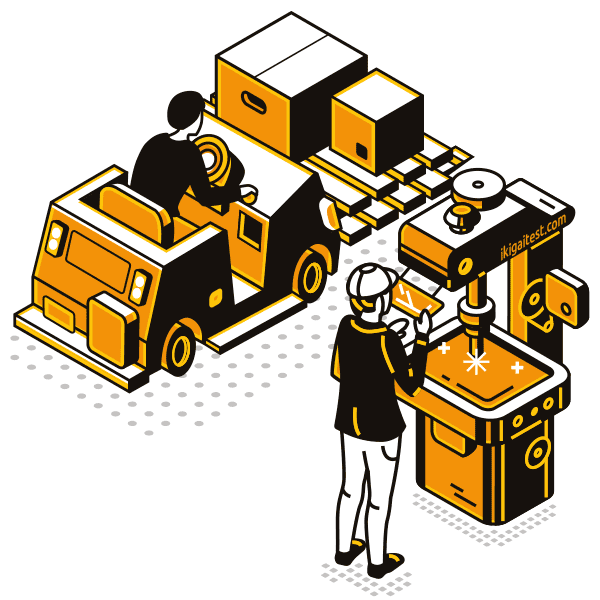

Operator

Operators are expected to be good at:

- Using either control mechanisms or direct physical activity to operate manufacturing systems.

- Working with hand operated industrial machines and power tools.

- Adjusting knobs, levers, and physical or touch sensitive buttons in industrial devices.

- Running, maneuvering, navigating, or driving vehicles or mechanized equipment, such as forklifts, passenger vehicles, aircraft, or watercraft.

Artisan

Great artisans are usually capable of:

- Using hands and arms in handling, installing, positioning, and moving materials.

- Performing precise and skillful manipulation of small objects.

- Being active and proactive in regards to physical activities that require considerable use of your arms and legs and moving your whole body, such as climbing, lifting, balancing, walking, stooping, and handling materials.

Other work activities related to Molding, coremaking, and casting machine setters, operators, and tenders, metal and plastic

- Observing continuous operation of automatic machines for ensuring that products meet specifications and for detecting jams or malfunctions, making adjustments as necessary.

- Measuring and visually inspecting products for surface and dimension defects for ensuring conformance to specifications, using precision measuring instruments.

- Setting up, operating, or tending metal or plastic molding, casting, or coremaking machines for molding or casting metal or thermoplastic parts or products.

- Positioning and securing workpieces on machines, and starting feeding mechanisms.

- Turning valves and dials of machines to regulating pressure, temperature, and speed and loading rates, and to setting cycle times.

- Removing finished or cured products from dies or molds, using hand tools, air hoses, and other equipment, stamping identifying information on products when necessary.

- Skim or pouring dross, slag, or impurities from molten metal, using ladles, rakes, hoes, spatulas, or spoons.