Operator

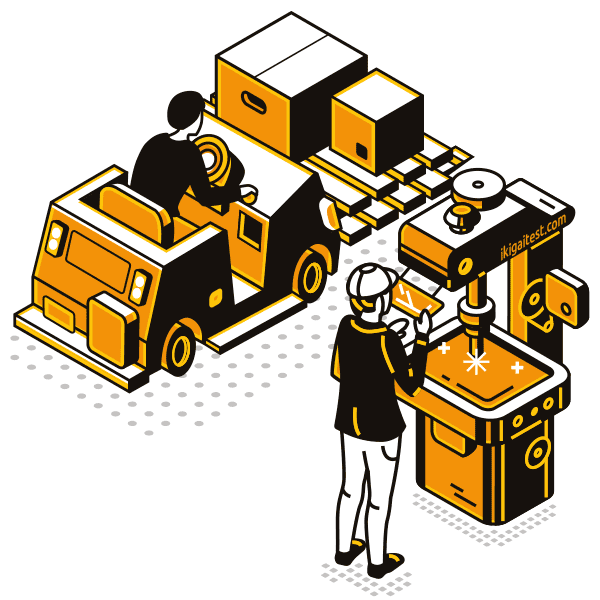

Operators are expected to be good at:

- Using either control mechanisms or direct physical activity to operate manufacturing systems.

- Working with hand operated industrial machines and power tools.

- Adjusting knobs, levers, and physical or touch sensitive buttons in industrial devices.

- Running, maneuvering, navigating, or driving vehicles or mechanized equipment, such as forklifts, passenger vehicles, aircraft, or watercraft.

Artisan

Great artisans are usually capable of:

- Using hands and arms in handling, installing, positioning, and moving materials.

- Performing precise and skillful manipulation of small objects.

- Being active and proactive in regards to physical activities that require considerable use of your arms and legs and moving your whole body, such as climbing, lifting, balancing, walking, stooping, and handling materials.

Other work activities related to Glass blowers, molders, benders, and finishers

- Inspecting, weighing, and measuring products for verifying conformance to specifications, using instruments such as micrometers, calipers, magnifiers, or rulers.

- Recording manufacturing information, such as quantities, sizes, or types of goods produced.

- Heating glass to pliable stages, using gas flames or ovens and rotating glass for heating it uniformly.

- Blowing tubing into specified shapes for preventing glass from collapsing, using compressed air or own breath, or blowing and rotating gathers in molds or on boards for obtaining final shapes.

- Setting up and adjusting machine press stroke lengths and pressures and regulating oven temperatures, according to glass types to be processed.

- Shaping, bending, or joining sections of glass, using paddles, pressing and flattening hand tools, or cork.

- Developing sketches of glass products into blueprint specifications, applying knowledge of glass technology and glass blowing.

- Determining types and quantities of glass required for fabricating products.

- Superimpose bent tubing on asbestos patterns for ensuring accuracy.